5 Things To Look For In A Quality Axe

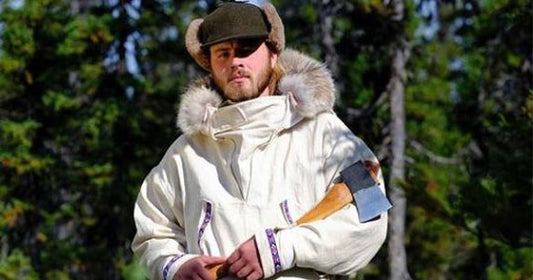

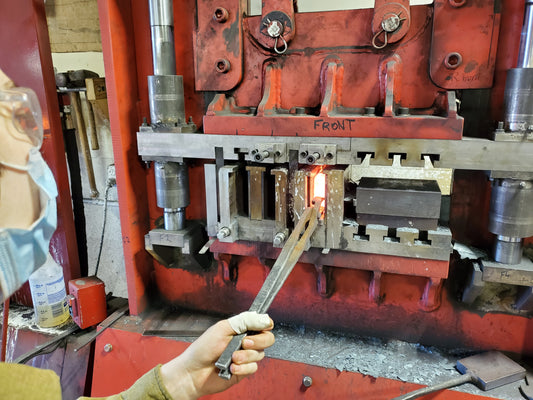

We are frequently asked what makes a Brant & Cochran axe so much better than one you buy at a big box hardware store. Is the extra money worth it? Of...

Read5 Things To Look For In A Quality Axe

We are frequently asked what makes a Brant & Cochran axe so much better than one you buy at a big box hardware store. Is the extra money worth it? Of...

Continue Reading

3 Easy Tips To Keep Your Axe Wicked Sharp!

It isn't hard to keep your axe wicked sharp and ready for work. Here are three simple rules to follow to make sure your axe is in tip top shape!

Read3 Easy Tips To Keep Your Axe Wicked Sharp!

It isn't hard to keep your axe wicked sharp and ready for work. Here are three simple rules to follow to make sure your axe is in tip top shape!

Continue Reading

Restoring Vintage Axes: 8 Steps to Breathing Ne...

Vintage axes possess a unique charm and craftsmanship that modern tools often lack. If you've stumbled upon a handcrafted axe hidden away in an old shed or inherited one from...

ReadRestoring Vintage Axes: 8 Steps to Breathing Ne...

Vintage axes possess a unique charm and craftsmanship that modern tools often lack. If you've stumbled upon a handcrafted axe hidden away in an old shed or inherited one from...

Continue Reading

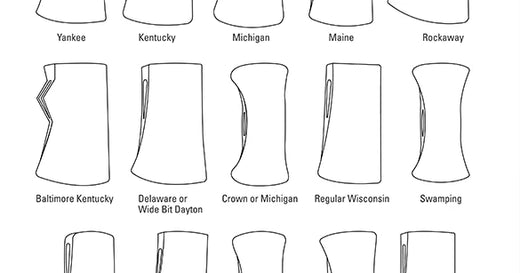

Get a Handle on It: Everything You Need to Know...

Many of you have heard our griping about finding proper axe handles to hang on our axes. Given the amount of time we spend wailing and gnashing our teeth about...

ReadGet a Handle on It: Everything You Need to Know...

Many of you have heard our griping about finding proper axe handles to hang on our axes. Given the amount of time we spend wailing and gnashing our teeth about...

Continue Reading

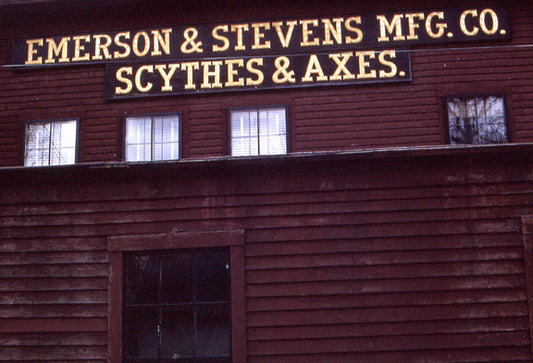

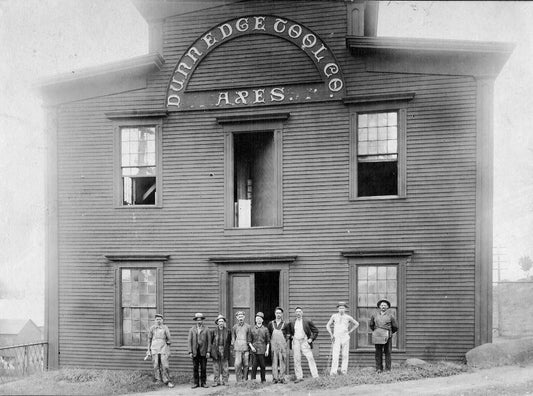

Secrets of the Emerson & Stevens Company - Part 2

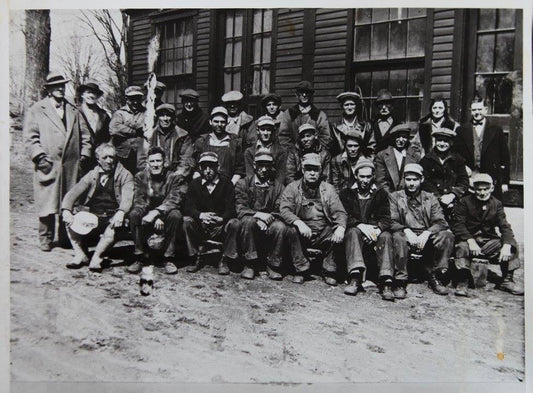

Tucked away in the Oakland Public Library are numerous treasures which shed light on that city's extensive axe making past. One such find is a letter dated April 20, 1965...

ReadSecrets of the Emerson & Stevens Company - Part 2

Tucked away in the Oakland Public Library are numerous treasures which shed light on that city's extensive axe making past. One such find is a letter dated April 20, 1965...

Continue Reading